PicoRaman M3 Measurement Probes Cleaning and Maintenance Guide

Discover the essential steps for maintaining optimal performance and prolonging the lifespan of your PicoRaman M3 spectrometer-compatible measurement probes. This comprehensive guide provides insights into effective cleaning techniques, inspection methods, and routine maintenance practices.

If you haven't had the opportunity to explore our blog about selecting the right measurement probe, we highly recommend reading it before delving into this post.

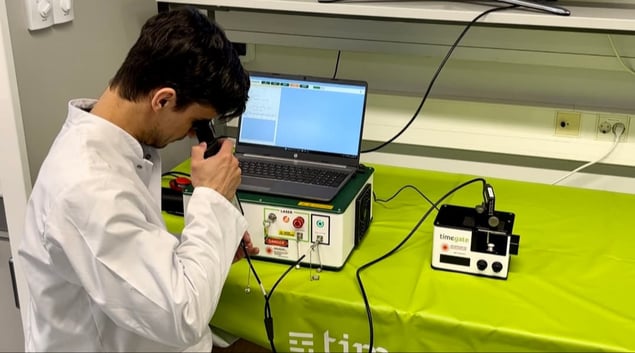

Regularly check and clean the fiber ends to maintain optimal performance and prolong the lifespan of your PicoRaman M3 spectrometer-compatible measurement probes. Timegate's Senior Application Specialist, Bryan Heilala, demonstrates how to inspect the fiber ends to ensure they are free of debris and ready for use.

Fiber end cleaning and inspection

One of the most important tasks is to ensure the cleanliness of the fiber ends of your measurement accessories when disconnecting from and connecting to your spectrometer. This also ensures that the fibers on the spectrometer’s side remain clean.

The fiber ends of the probe should be checked with a fiber microscope every time before they are connected to ensure optimal performance and longevity.

The probe’s fiber ends should be checked with a fiber microscope every time before they are connected. If any dirt is observed, cleaning with purpose-built equipment should take place before proceeding. Only suitable lint-free and non-abrasive tools should be used. Even after cleaning the fiber ends, the result should be checked with a fiber inspection microscope to make sure that the dirt has been removed and that no particles or solvents are left from the cleaning procedure. The fiber ends may hold a static charge meaning that they may easily attract dust if left unattended after cleaning. It is advisable that the fibers are connected immediately after cleaning and inspecting the fiber ends.

The PicoRaman M3 spectrometers are equipped with high-quality cleaning tools that facilitate effective fiber end inspection and cleaning.

Equipment designed for cleaning fiber ends includes many kinds of cleaning dry tape/cloth spools and cleaning pens. Always read and follow the documentation provided with the fiber cleaning tools. PicoRaman M3 spectrometers are shipped with a handheld microscope for fiber inspection and tools for cleaning fiber ends.

Cleaning techniques for fiber connectors and other probe components

In most cases, dry cleaning will be sufficient for removing observed debris from the fiber end surfaces. In more challenging cases wet cleaning may be required with e.g., alcohol or fiber cleaning fluids. It should be noted that some alcohol denaturation additives may leave residue on the fiber surface, and these should be avoided. The use of excessive amounts of solvent may also cause challenges including cross-contamination and streaks on the fiber surface. An effective method for avoiding this and achieving optimal results is to use a wet-to-dry cleaning process where the fiber end is first cleaned with a small amount of liquid (e.g., a damp cleaning cloth) after which the fiber is cleaned with a dry method.

If the fiber connectors are not kept clean, this may result in fiber surfaces that are very difficult to clean without polishing the whole surface. This may especially be the case when using high-power pulsed lasers (as with PicoRaman M3) where debris and dirt may be burned on the fiber surface, particularly on the excitation/illumination fiber side. It should also be noted that the sides of the fiber end connector may become dirty over time and may require cleaning.

Neglecting the cleaning and inspection procedures between removing and re-attaching measurement probes can result in a grimy and impaired fiber end (pictured above), leading to poor performance and a shorter lifespan.

While cleaning the probe fiber ends generally keeps the spectrometer’s fiber connectors and fiber ends clean, the connector can be cleaned with several kinds of (often pen- or stick-like) cleaning tools that can be inserted into the fiber connector. It needs to be taken care of that these tools do not push in or introduce debris into the connector. If fiber connectors are disconnected and reconnected often, it is usually a good idea to also illuminate and visually check the inside of the fiber connector port (switch off laser!) to see if any debris is visible.

Suitable cleaning tools for spectrometer fiber connector ports include various types of cleaning pens or sticks.

Other parts of the probes should also be kept clean. This holds especially true for the front optics/window. If the probe’s front window/optics are dirty, the data collection efficiency will decrease, and it may produce artifacts in the measurement results. When cleaning the probe shaft, it must be taken into account whether the probe is an immersion probe or not. Non-immersion probes should be cleaned with a small amount of cleaning liquid (e.g., a damp cloth) and should not be immersed for cleaning. Even with immersion probes, only certain parts of the probe may be waterproof. Always check probe-specific documentation for cleaning instructions. The front window/optics material may be glass, sapphire, or some other fragile material that may not withstand impacts. Softer materials may also scratch easily.

The probe front window/optics should be kept clean for optimal measurement results.

In some cases, a probe may need treatment in an autoclave before it can be used for measurement purposes. It should always be checked which parts of the probe are autoclavable. In the case of a ProbePro Mini probe, only the outer detachable SCHOTT ViewPort® part is autoclavable, and the rest of the probe should not be exposed to autoclaving. With a detachable part like the ViewPort®, it should also be checked that no dirt gets into or between parts.

Attaching the waterproof and autoclavable SCHOTT ViewPort® around the ProbePro Mini probe shaft enables sterile immersion measurements.

Handling fiber cables and troubleshooting tips

In addition to the fiber ends, the fiber cables themselves are also somewhat sensitive and will not withstand abuse. Depending on the fiber cable type, the fibers may be protected by different material layers including polymers, metals, and composites. The fiber cables should not be stored or used while being stretched or overly tightly wound and the fibers should never be bent. If the movement of the probe’s fiber cables (while the probe body and shaft are stationary) causes significant changes in the excitation or collection efficiency, the cable connection to the spectrometer should be checked first. If the connection is without fault, the next step may be to question the integrity of the fiber cable.

Importance of routine probe cleaning, maintenance and performance testing

By following these guidelines for cleaning, inspection, and routine maintenance, you can optimize the performance and longevity of your PicoRaman M3 measurement probes. Invest in the proper care and maintenance to ensure accurate and reliable results for your analytical processes.

With time-gated Raman measurements, it is also recommended to measure a well-known reference sample with standard measurement settings in a repeatable manner and make sure that the results are within an acceptable range. This testing should also reveal if something has happened to a measurement probe.

Watch the PicoRaman M3 spectrometer and ProbePro Mini demonstration video:

Author

This blog was written by Timegate Instruments’ Senior Application Specialist Bryan Heilala. Bryan is a young and energetic chemist with a degree in M.Sc. (chemistry) and experience and background in analytical chemistry. Read more about him and the whole Timegate team.

This blog was written by Timegate Instruments’ Senior Application Specialist Bryan Heilala. Bryan is a young and energetic chemist with a degree in M.Sc. (chemistry) and experience and background in analytical chemistry. Read more about him and the whole Timegate team.