Raw material quality control with Timegated® Technology

Timegated® Raman Technology –

Raw Material Quality Control in biopharmaceutical batch processes involves a systematic approach to evaluating and monitoring the quality of raw materials used in the production of biopharmaceuticals.

Media Quality Control: Media in biopharmaceutical processes provides the necessary nutrients for cell growth and product formation. The aim is to ensure homogeneity of media from batch to batch.

Component Quality Control: Raw materials in biopharmaceutical processes directly impact the quality and characteristics of the final product. The quality of raw materials used in the biopharmaceutical production processes needs to be tested and analyzed.

The challenge of variations in the composition of media and raw material components among batches result in unstable production conditions

Variability in media quality and repeatability between batches can lead to an unstable starting point for each batch. Maintaining a stable and standardized starting point is essential for achieving reproducibility and meeting regulatory requirements.

Process analysis: The measurements of media parameters are not accurate enough to ensure that the media remains consistent from batch to batch.

Data analysis: In media quality control, efficient data analytics is challenging, as there is not always sufficient data available for tracking relevant parameters and optimizing them.

Timegate enables a stable starting point for each batch, and enhances overall process consistency

Timegate provides process analytical tools and technologies for real-time monitoring and control from the beginning throughout the entire biopharmaceutical manufacturing process. With Timegated® Raman Technology there is no need for sample preparations, and it enables non-destructive analysis of media and raw material components.

Process analysis: Timegate’s process analytical tools indicate whether the media is homogeneous from batch to batch regardless of the sample size. There is no need for you to manipulate the sample before measurements.

Data analysis: Time-gated technology (link to technology page) suppresses the interfering fluorescence enabling you to catch data that has not been seen before with conventional Raman spectroscopy, even in small samples. For data analytics, Timegated® Raman spectroscopy provides a large set of real-time data for analyzing various parameters and ensuring raw material quality control in bioprocessing.

Raw material quality control with Microplate HTS System: Automated measurements with non-destructive method for real-time and accurate data.

Monitoring and analyzing biotechnological cultures

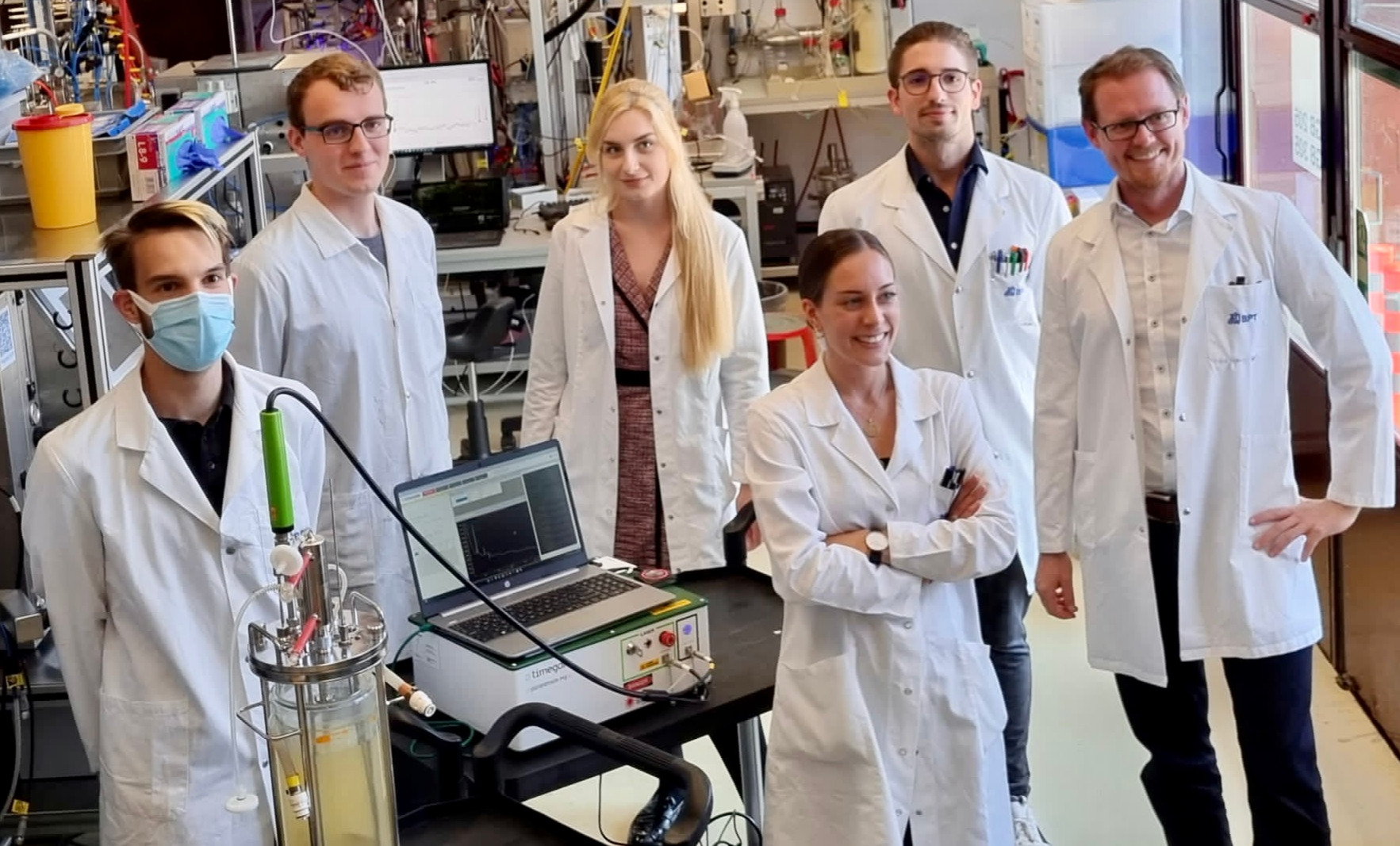

The priority objective for the Bioprocess Technology team of Zurich University of Applied Sciences (ZHAW) in working with the PicoRaman M3 is monitoring and analyzing biotechnological cultures.