Testa Challenge results: accurate predictions with Timegated® Raman

Following our long journey with the Testa Challenge - where we spent nearly three weeks on-site, conducting in-depth analysis and modeling of the Raman spectra, as well as studying and presenting our findings - we are thrilled to finally share the encouraging results of our bioprocess monitoring with all of you.

If you have not had the chance to follow our journey previously, you can read more here: Timegate in Testa Challenge!

Timegators during the last days of the Testa Challenge. From left Dr. Amutha Daniel, Elina Aronen-Raappana, Mari Tenhunen, Roosa Klaavo and Vineeth Karuppasamy.

Timegated® Raman prediction follows the reference values perfectly

Testa Challenge results in a video format.

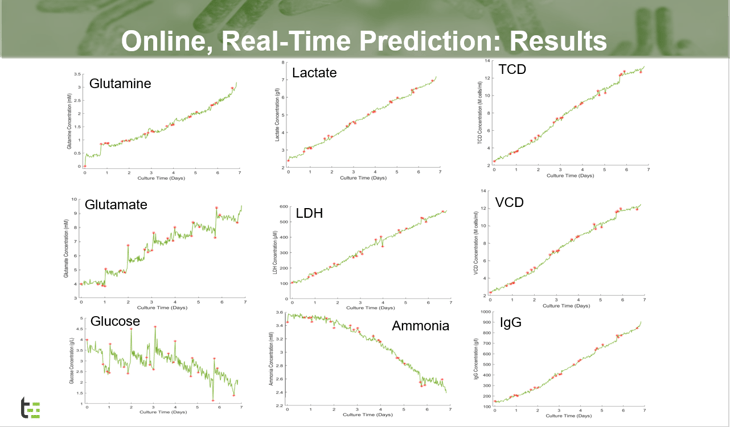

In the Testa Challenge, we were monitoring the Chinese hamster ovary (CHO) cells which are the most common mammalian cell line. We measured several metabolites, nutrients, and proteins in real-time in bioreactors during the whole biopharmaceutical process. All these parameters were measured simultaneously.

In the graphs below, the red marks represent the reference values obtained from laboratory analysis. The green curve is the result of Raman analysis. As can be seen here the Raman prediction is perfectly following the reference values and therefore highly accurate.

This technique holds the promise of measuring not only the critical parameters but also the product that is being produced effectively. Read more about time-gated technology.

Time-gated Raman analyses (green curves) follow accurately the reference values obtained from laboratory analyses (red marks).

Improved bioprocess control with time-gated Raman technology

Looking at the results, we can see that the benefits of time-gated Raman technology for the bioprocess development and control are significant:

- New medicines faster to market by better understanding the process mechanisms

- Decreased number of process failures by better understanding the processing status in the production phase

- Optimized process control and improved productivity as well as product quality with real-time data of the parameters

- Reduced operational costs by not needing analytical consumables with our technology and saving the analytical professionals’ time

Stay tuned and find out, what exactly was the target of these measurements. Follow us on LinkedIn and Twitter if you want to be the first to know.