FAQ: How to Avoid Sample Alteration Due to Laser Exposure?

FAQ series: This series of publications explores some of the most frequently asked questions regarding Timegated® spectrometers and measurements without having you read page after page of text.

Some surface analytical techniques are based on altering (e.g. ablation) sample surfaces. Other techniques, like Raman spectroscopy, usually aim to keep sample surfaces intact during a measurement as surface alteration might affect the results.

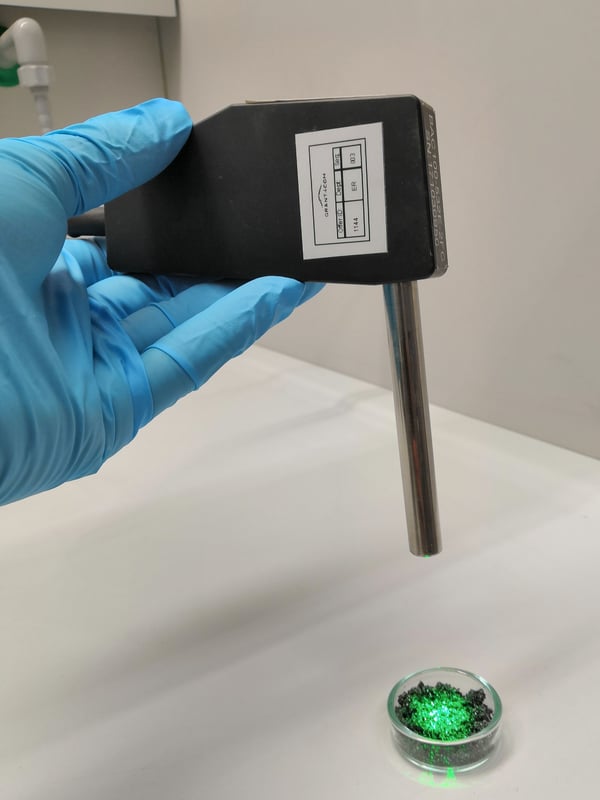

Using high excitation laser power may enable effective collection of Raman information in a relative short measurement but it is important to check if the measured material can withstand the laser exposure as laser sensitivity varies significantly depending on the sample type. Next, we are going to look at some of the more common methods of minimizing any possible sample alteration due to laser exposure.

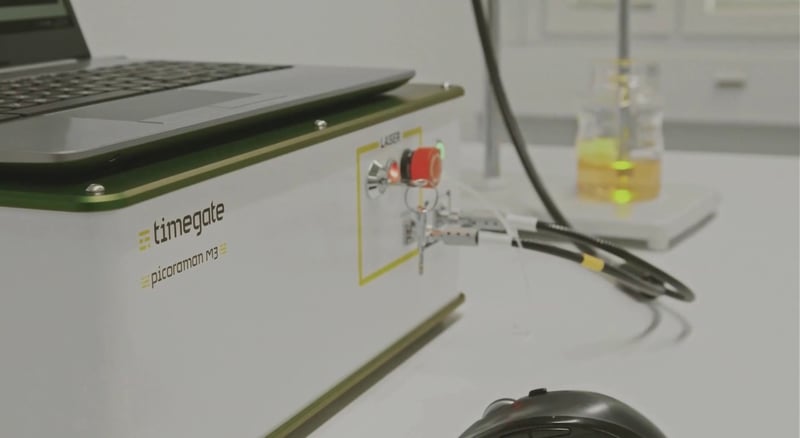

- Lower your laser power. Lowering excitation laser power might require you to make your measurements slightly longer, but most often it is worth it if sample damage can be avoided. Timegate Instruments' PicoRaman spectrometers offer easy GUI options for the adjustment of measurement laser power.

- Limit your measurement length. The sample alteration often progresses and worsens as the laser exposure is extended. Could measurement results with acceptable signal to noise ratios be achieved with shorter measurements?

- Use a larger illumination spot. Not focusing all the laser power on a miniscule measurement spot may help avoiding sample alteration. Depending on the measurement probe and optics, this might lessen the collection efficiency especially if using very large illumination spots.

- Don’t focus the laser exactly on the sample surface. If the laser power cannot be lowered any further or the illumination spot cannot be changed, this might be worth a try. By not exactly focusing the laser on a single point on the sample, sample alteration is usually significantly reduced. It should be noted though, that this “off-focus” technique substantially reduces the collected Raman information, and this method shouldn’t normally be used as the first option to limit laser exposure.

- Move the sample or the laser spot during measurements. Limiting the continuous laser exposure of a single sample spot might help. This may also help to provide more representative measurement results as a larger part of the sample is measured. The Timegate Instruments' SampleCube provides the option to both rotate the sample and simultaneously move the measurement probe in a controlled manner.

- Wet the sample. A wet sample is often less likely to burn/oxidize. As Raman spectroscopy is not too sensitive for water, the water addition doesn’t interfere with most applications. If the water seems to evaporate too fast, you might want to try to measure the sample through a glass cover or in a glass container.

- Measure the sample in inert gas. An inert gas atmosphere or stream reduces the probability of accelerated sample oxidization due to laser exposure.

- Cool the sample. A cold or frozen sample is often less reactive and less likely to burn due to laser exposure.

- Remove sensitive particles. Sometimes only certain particles or impurities might be sensitive to laser exposure. Removing these components may help with allowing for more reproducible measurements.

- Avoid measuring sensitive particles. If laser sensitive parts or particles are not of interest, then they may be avoided by using e.g. a microscope setup that allows for choosing the exact measurement spot.

- Use an excitation laser with a different wavelength. Swapping out the laser or adjusting the laser wavelength might not always be possible but as different sample types may have differences in absorption of light in certain wavelengths, this might reduce any possible sample alteration. Strong absorption in the wavelength range of the excitation laser usually leads to sample heating and may lead to sample damage.

Author

This blog was written by Timegate Instruments’ Application Team Lead Bryan Heilala. Bryan is a young and energetic chemist with a degree in M.Sc. (chemistry) and experience and background in analytical chemistry.

This blog was written by Timegate Instruments’ Application Team Lead Bryan Heilala. Bryan is a young and energetic chemist with a degree in M.Sc. (chemistry) and experience and background in analytical chemistry.