Raman Spectroscopy | 30.06.2022

Share this article:

Related articles

Raman Spectroscopy | 01.02.2023

Timegate as part of Bioindustry4.0

Timegate is one of the organizations in Bioindustry4.0 encouraging the adoption of advanced digital...

Events | 12.01.2023

Timegated® Raman Seminar in Italy

Join us at the Timegated® Raman Seminar in Italy on February 14th! Presentations about the...

Raman Spectroscopy | 15.12.2022

Timegate is launching a Service Business

Timegate Instruments is launching a Service Business and offering sample measurements for our...

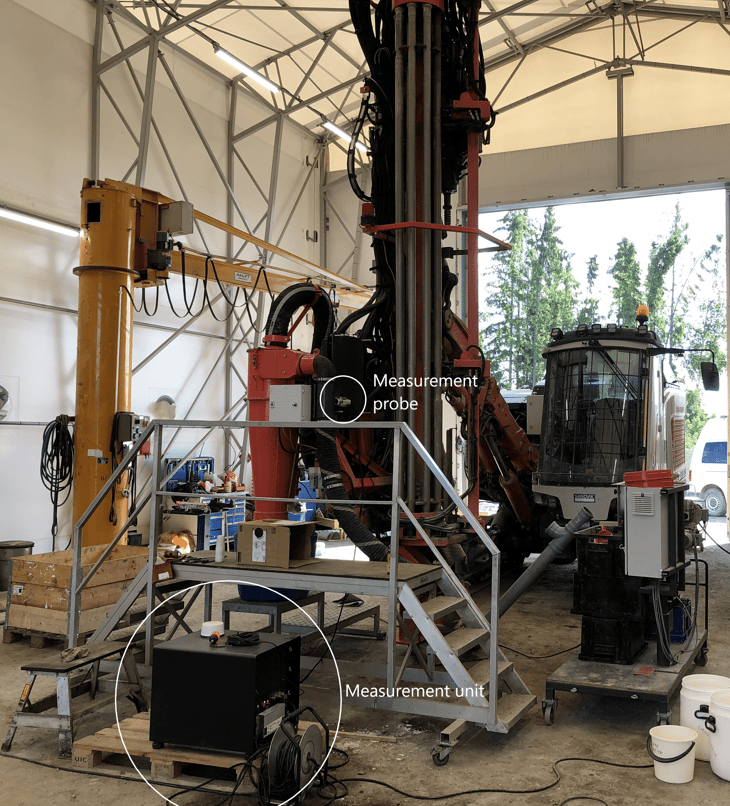

Timegated® Raman monitoring system installed into the drilling unit.

Timegated® Raman monitoring system installed into the drilling unit. Close-up of the installed Timegated® Raman Probe.

Close-up of the installed Timegated® Raman Probe.